I accept VadaTech copyright information.

Home

Products

Newsroom

By Function

|

I accept VadaTech copyright information.

Please enter your email registered at VadaTech and we will send you your password.

VadaTech provides a support infrastructure to help customers meet their lifecycle management requirements. This addresses all product phases, including the critical transition from prototype to deployable product and through to in-service life extension.

Where customers are looking to deploy in harsh environments, production hardware can often have extended lead times. The use of standard architectures, such as MicroTCA, together with an extensive range of modules and chassis, will generally allow prototyping to proceed on standard product with a very smooth transition to deployable hardware once available. This can have significant benefits to a project in reduced risk and schedule.

OEMs and defense primes need to be confident that product lifecycle is well managed and any obsolescence risks addressed. During an initial design phase for a new project, all bill of material components are analyzed for obsolescence prior to incorporation into the design. This bill of material analysis is then continuously performed periodically through the product lifecycle. VadaTech includes proactive obsolescence forecasting and mitigation for applicable part types, and plans for reacting and achieving solutions to obsolescence impacts as they occur and before they affect a program. In the event obsolescence issues arise during a project lifecycle, VadaTech can provide timely notification to customers identifying risks and offering mitigation strategies.

With many products used in long-life mil/aero programs, VadaTech is able to offer stock-holding (either of product or of components reaching obsolescence) for extended availability. Technical support can also be provided for customers wishing to transition to a form-, fit- and function-equivalent replacement.

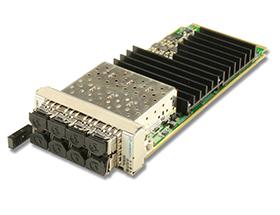

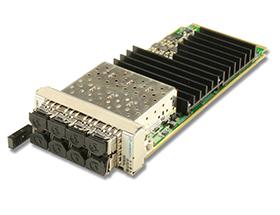

Examples of long-life legacy products include interface products such as AMC604 and AMC205